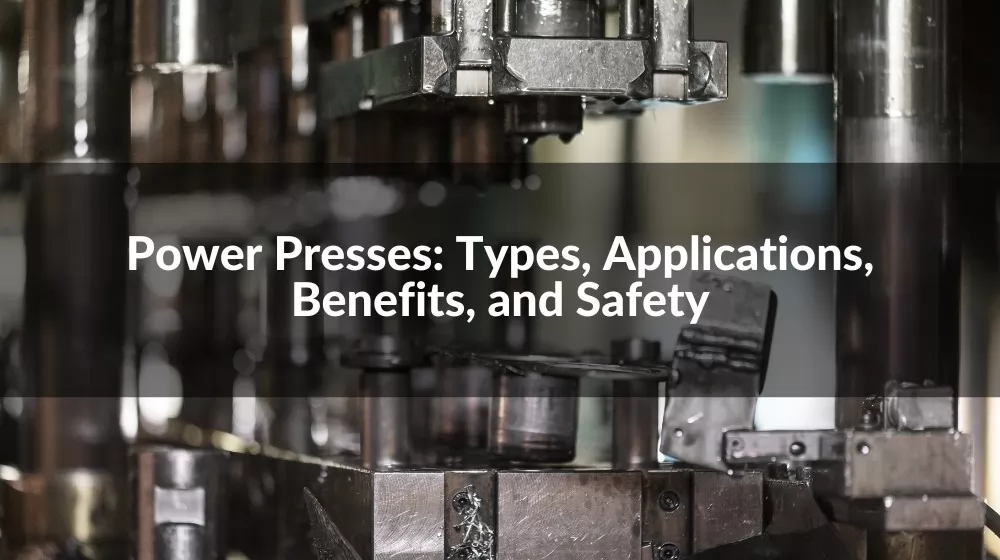

Welcome to the comprehensive guide on Power Press technology – a pivotal tool in modern manufacturing that revolutionizes the way we shape, cut, and form materials. From the automotive industry to consumer electronics, Power Presses are at the heart of production lines, combining efficiency with precision. This article delves into the various types of Power Presses, their applications, benefits, and the latest innovations shaping their future. Join us as we explore how these powerful machines are transforming industries and what to consider when selecting the right Power Press for your manufacturing needs.

In the dynamic world of manufacturing, Power Press technology stands out as a cornerstone for countless industries. This innovative machinery, known for its precision and efficiency, has revolutionized the way we approach mass production. At its core, a Power Press is a machine that changes the shape of a workpiece by applying pressure. Whether for cutting, punching, bending, or shaping, these machines play a pivotal role in the fabrication of metal parts and components.

The essence of Power Press technology lies in its versatility. Ranging from manual to fully automated systems, these presses are designed to meet diverse manufacturing needs. They can be categorized into two main types: mechanical presses and hydraulic presses. Mechanical presses utilize a motor to drive the ram, offering speed and consistency for high-volume production. On the other hand, hydraulic presses use hydraulic oil as a pressurizing medium, providing unparalleled control and flexibility in pressure application, ideal for intricate shapes and materials.

The applications of Power Press machines are vast and varied. They are indispensable in the automotive, aerospace, and electronics industries, where precision and reliability are paramount. From creating small components like screws and bolts to forming large automotive panels, the capabilities of these presses are limited only by the imagination of the designers.

However, with great power comes great responsibility. The safety of operators is paramount in the design and operation of Power Presses. Advances in technology have led to the integration of safety features such as light curtains, double-hand controls, and automatic shut-off mechanisms, significantly reducing the risk of accidents.

In conclusion, Power Press technology is a testament to human ingenuity in the pursuit of industrial efficiency and productivity. Its evolution continues to offer promising solutions to the challenges of modern manufacturing, making it a key asset for businesses looking to stay competitive in a global market.

A Power Press is more than just a piece of machinery; it's a fundamental tool in the manufacturing industry, defined by its ability to exert force on a workpiece to alter its shape. This definition encapsulates a range of operations, including stamping, punching, bending, and shearing, making it a versatile ally in metal forming processes. Its significance lies not only in its functional diversity but also in its impact on production efficiency and precision.

The significance of Power Press technology in today's industrial landscape cannot be overstated. It serves as the backbone for high-volume manufacturing, enabling companies to produce parts at an unprecedented rate while maintaining high standards of quality and consistency. This efficiency is pivotal for industries where the demand for precision-engineered components is incessant, such as in automotive, aerospace, and consumer electronics.

Moreover, the evolution of Power Press machinery has closely mirrored advancements in automation and safety standards. Modern presses are equipped with sophisticated control systems that optimize production cycles, reduce waste, and ensure the safety of operators. This integration of technology enhances the machine's significance, making it not only a tool for shaping materials but also a catalyst for innovation and sustainability in manufacturing.

In essence, the Power Press embodies the convergence of strength, precision, and technological advancement. Its role in fabricating components that form the building blocks of various industries underscores its significance. As we continue to push the boundaries of what's possible in manufacturing, the Power Press remains at the forefront, shaping the future one press at a time.

Power Presses are categorized into various types based on the mechanism they use to deliver force. The most common types are Mechanical Power Presses, Hydraulic Power Presses, and Pneumatic Power Presses. Each type has its unique advantages and applications, making them suited for different manufacturing needs.

Mechanical Power Presses operate on an electric motor that drives a mechanical flywheel, converting rotational motion into linear motion to exert force. Known for their speed and efficiency, these presses are ideal for high-volume production runs. They offer consistent stroke lengths and speeds, which can be advantageous for operations requiring uniformity and precision.

Hydraulic Power Presses utilize hydraulic cylinders to generate force. The pressure within the hydraulic fluid is used to move the press's ram, allowing for more precise control over the speed and position of the press. This type is highly valued for its ability to apply a wide range of forces, making it suitable for applications requiring intricate shapes and materials.

Pneumatic Power Presses use compressed air to exert force on the workpiece. These presses are known for their simplicity and speed, offering quick, efficient operations with lower forces compared to hydraulic presses. They are commonly used for smaller, repetitive tasks where high speed and lower cost are prioritized.

When comparing these types of Power Presses, it's important to consider the specific requirements of the manufacturing process. Mechanical presses are best suited for high-speed, high-volume production with consistent results. Hydraulic presses offer versatility and precision, ideal for complex shapes and varying material thickness. Pneumatic presses, on the other hand, are optimal for operations requiring fast, repetitive actions with less force.

Each type of Power Press brings a unique set of benefits to the table. The choice between them depends on factors such as desired output, material type, and the complexity of the task. By understanding the capabilities and advantages of each, manufacturers can select the most appropriate press type to meet their production needs and achieve optimal results.

The frame and construction of a Power Press are critical to its performance, durability, and safety. This chapter delves into the material considerations and design variations that play a pivotal role in the functionality of Power Presses.

The choice of material for constructing Power Presses is guided by the need for high strength, durability, and resistance to wear and tear. High-grade cast iron and steel are the most commonly used materials. Cast iron offers excellent vibration dampening properties, making it ideal for reducing noise and extending the life of the machine. Steel, on the other hand, provides superior strength and flexibility, which is crucial for withstanding the high stresses involved in pressing operations.

Moreover, the specific type of steel, such as carbon steel or alloy steel, is selected based on the required properties. Alloy steels, for example, are preferred for components that demand higher toughness and resistance to impact. The materials are also treated with various heat treatments and coatings to enhance their properties and protect against corrosion, further extending the lifespan of the Power Press.

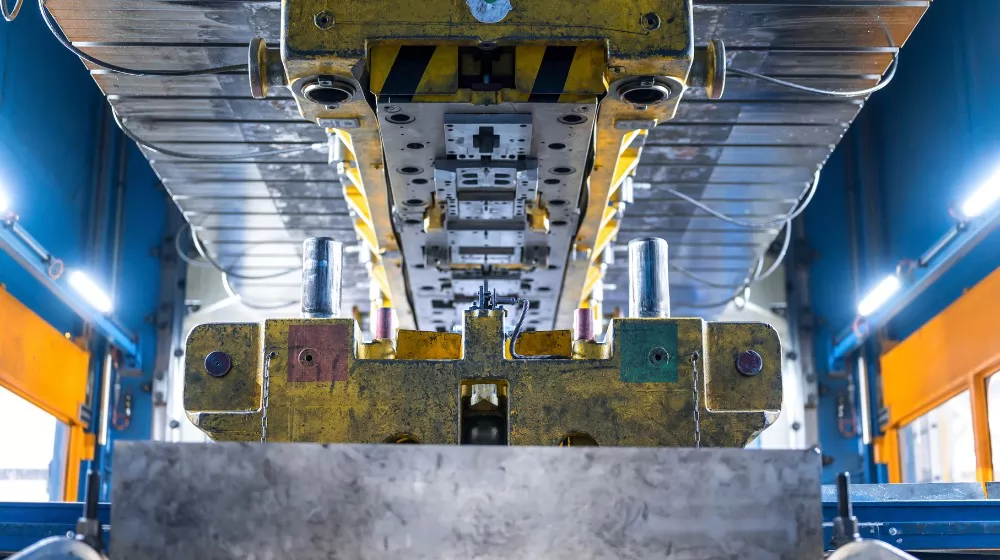

Power Press frames come in several design variations, each tailored to specific applications and workloads. The most common designs are the C-frame and H-frame configurations. C-frame presses offer accessibility on three sides and are preferred for their compact footprint, making them suitable for smaller workspaces. They are ideal for applications requiring moderate pressing force.

H-frame presses, also known as four-column presses, provide uniform distribution of force over a larger work area. This design is favored for its stability and ability to handle higher forces, making it suitable for demanding operations such as deep drawing and forging. Additionally, the construction of Power Presses often includes features such as adjustable stroke lengths, built-in overload protection, and customizable bed sizes to accommodate a wide range of tasks.

Innovations in design also focus on enhancing operator safety and ease of use. Ergonomic features, such as adjustable controls and user-friendly interfaces, are increasingly common. Moreover, the integration of advanced sensors and monitoring systems ensures precise control over the pressing process, further optimizing performance and safety.

In conclusion, the frame and construction of Power Presses are integral to their operational efficiency. Through careful consideration of materials and innovative design variations, manufacturers can achieve a balance between performance, durability, and safety, ensuring that these machines meet the rigorous demands of modern manufacturing environments.

The drive mechanism of a Power Press is what converts the motor's rotational motion into the linear motion needed to apply force on the workpiece. This chapter highlights the critical components of drive mechanisms, including Eccentric Shafts and Crankshafts, as well as Gears and Clutches, and their roles in the operation of Power Presses.

Eccentric Shafts and Crankshafts are at the heart of mechanical Power Presses. They transform the circular motion of the motor into a straight-line motion. Crankshafts work by converting the rotational motion into a reciprocating motion through the crank and connecting rod mechanism. This setup is known for its reliability and is widely used in high-speed presses. Eccentric Shafts, on the other hand, allow for the adjustment of the stroke length, providing flexibility in the pressing process and making them ideal for applications requiring different stroke lengths for various tasks.

Gears play a pivotal role in transmitting power from the motor to the press mechanism. They ensure that the press operates at the correct speed and torque, enhancing the machine's efficiency and control. The use of gears also allows for the adjustment of the press speed, accommodating different materials and thicknesses.

Clutches are another crucial component, enabling the operator to engage and disengage the drive mechanism. This capability is essential for starting and stopping the press, ensuring precise control over the pressing process. There are various types of clutches used in Power Presses, including mechanical, pneumatic, and hydraulic clutches. Each type offers different characteristics in terms of response time, durability, and maintenance requirements, affecting the overall performance and safety of the press.

In summary, the drive mechanisms of Power Presses, including Eccentric Shafts and Crankshafts, Gears, and Clutches, are fundamental to their operation. These components ensure that the presses deliver the required force accurately and efficiently, making them indispensable in the manufacturing industry. Their design and functionality directly impact the press's performance, versatility, and safety, highlighting the importance of selecting the right components for specific manufacturing needs.

The sophistication of a Power Press's control system directly impacts its efficiency, safety, and usability. Control systems in Power Presses range from manual to semi-automatic, and automatic controls, each offering different levels of operational complexity and automation. Additionally, the integration of safety interlocks and monitoring systems plays a critical role in ensuring operator safety and maintaining production quality.

Manual control systems require operators to initiate and control the press's operations directly, offering high levels of control but at the expense of speed and consistency. Semi-automatic systems, meanwhile, automate part of the process while still requiring some level of operator input, striking a balance between automation and control. Fully automatic control systems are at the forefront of Power Press technology, capable of running entire production cycles with minimal human intervention. These systems are equipped with programmable logic controllers (PLCs) and computer numerical controls (CNCs), which allow for precise adjustments and repeatability, significantly increasing production efficiency and reducing the likelihood of errors.

Safety interlocks and monitoring systems are essential features of modern Power Press control systems. Safety interlocks prevent the press from operating under unsafe conditions, such as when guards or doors are open. Monitoring systems, including sensors and cameras, continuously assess the press's performance and condition, detecting anomalies that could indicate potential safety issues or maintenance needs. These systems are critical for preventing accidents and ensuring the press operates within its design parameters, thereby protecting both the operators and the equipment.

The integration of advanced control systems and safety technologies in Power Presses has transformed them into highly efficient and safe machines. Manufacturers now have the ability to achieve higher production rates, maintain stringent quality standards, and ensure the safety of their workforce, all thanks to these sophisticated control and monitoring systems. As technology advances, we can expect to see further enhancements in control systems, making Power Presses even more integral to the manufacturing industry.

Setting up a Power Press is a critical process that requires careful consideration of installation requirements, initial setup, and calibration. Proper installation is not only crucial for ensuring the machine operates efficiently but also for maintaining workplace safety. This chapter provides insights into the foundational steps necessary for preparing a Power Press for operation.

The installation of a Power Press begins with a thorough evaluation of the designated area. It requires a solid, level foundation capable of supporting the weight and vibrations of the press. Adequate space around the machine is essential for safe operation and maintenance activities. Additionally, electrical installations must meet the power requirements of the press, including proper grounding and electrical protection to ensure safety and reliability. Environmental considerations, such as lighting, temperature control, and ventilation, also play a vital role in maintaining optimal operating conditions and worker comfort.

Once the Power Press is properly installed, the initial setup and calibration are crucial for precise operation. This process involves adjusting the machine to the specific requirements of the production task. Calibration ensures that the press operates within its intended parameters, delivering the correct force and accuracy for the job. It includes setting the stroke length, pressure adjustments, and aligning the dies correctly. Technicians may use a variety of instruments and techniques to measure and adjust the press, ensuring that it meets the necessary specifications for the task at hand.

Proper setup and calibration are not one-time tasks but ongoing requirements to ensure the Power Press continues to operate efficiently and safely. Regular maintenance checks and recalibrations are necessary to adjust for wear and tear, changes in production materials, or shifts in product specifications. This proactive approach to maintenance helps prevent downtime, extends the life of the press, and ensures consistent product quality.

In summary, the successful setup of a Power Press is a comprehensive process that encompasses careful planning, precise installation, and meticulous calibration. By adhering to these guidelines, manufacturers can maximize the efficiency and longevity of their Power Presses, ensuring they remain a valuable asset in the production process.

Efficient and safe operation of a Power Press relies on adhering to established operating procedures. These procedures are designed to ensure the machine's longevity, protect the safety of the operators, and maintain optimal production quality. This chapter focuses on the daily startup routine and the best practices for material handling and feeding into the Power Press.

A consistent daily startup routine is vital for the smooth operation of a Power Press. This routine should begin with a visual inspection of the machine, checking for any signs of wear or damage that may have occurred during the previous operation. Following the inspection, operators should lubricate all moving parts to minimize friction and wear. The next step involves verifying the safety systems, such as guards and emergency stop buttons, to ensure they are functioning correctly. Once these checks are completed, the machine can be powered on, and a test run with no material should be conducted to confirm that the press operates smoothly and correctly.

Proper material handling and feeding are crucial for the efficiency and safety of Power Press operations. Materials should be inspected before loading to ensure they are free from defects and suitable for processing. The method of feeding material into the press depends on the type of operation being performed. Manual feeding requires the operator to place the material accurately within the press, adhering to all safety protocols. For high-volume production, automatic feed systems may be used, which precisely position the material for each operation, enhancing productivity and reducing the risk of operator injury.

Regardless of the feeding method, it's essential to ensure that the material is correctly aligned and secured before initiating the press cycle. Misalignment can lead to defective products, damage to the press, or even injuries. Consequently, operators must be thoroughly trained in material handling and feeding procedures, emphasizing the importance of attention to detail and adherence to safety standards.

In conclusion, the daily operation of a Power Press involves a series of critical procedures designed to ensure the machine's effective and safe use. From the initial startup routine to the careful handling and feeding of materials, each step contributes to the overall success of the manufacturing process. By following these guidelines, manufacturers can achieve high levels of productivity while maintaining a safe working environment.

The longevity and efficiency of a Power Press depend significantly on regular maintenance and the ability to troubleshoot common issues promptly. Establishing a routine maintenance schedule and understanding the most common problems and their solutions can drastically reduce downtime and extend the lifespan of the machine. This chapter outlines the essential maintenance practices and troubleshooting tips for Power Press operators.

A well-planned routine maintenance schedule is crucial for the smooth operation of a Power Press. Daily tasks should include cleaning the machine to remove debris and checking for any loose components. Weekly maintenance might involve inspecting the lubrication system to ensure all moving parts are adequately lubricated and functioning smoothly. Monthly checks can focus on more in-depth inspections, such as examining the electrical system, safety features, and structural integrity of the press. Additionally, it's vital to schedule annual professional inspections to identify and address any potential issues that may not be evident to the daily operator.

Despite regular maintenance, Power Presses can experience common issues that may impact their performance. One frequent problem is misalignment of the die, which can lead to inaccurate parts or damage to the machine. This issue can usually be resolved by recalibrating the die setup. Another common issue is excessive noise or vibration, often caused by loose components or inadequate lubrication. Tightening any loose parts and ensuring all moving parts are well-lubricated can typically mitigate these problems.

Electrical issues, such as erratic operation or failure to start, can often be traced back to faulty wiring or problems with the control system. These issues require a thorough inspection of the electrical components and may necessitate professional repair. Lastly, hydraulic or pneumatic systems may experience leaks or pressure drops, affecting the press's operation. Regularly checking for leaks and ensuring the systems are properly pressurized can help maintain optimal performance.

In summary, routine maintenance and effective troubleshooting are essential for maximizing the performance and lifespan of a Power Press. By adhering to a scheduled maintenance plan and being prepared to address common issues, operators can ensure their Power Press remains a reliable and efficient tool in the manufacturing process.

The integration of robotics and automation in Power Press operations marks a significant leap forward in manufacturing efficiency and workplace safety. Automation technologies not only streamline production processes but also minimize the risks associated with manual operation. This chapter explores the advancements in robotics and automation integration in Power Presses and their impact on efficiency and safety.

Modern Power Presses are increasingly being integrated with robotics and sophisticated automation systems. These systems are designed to automate tasks such as material handling, loading, and unloading, which traditionally required manual intervention. Robotics can precisely position materials, ensuring accuracy and consistency in production. Automation also extends to the control systems of Power Presses, where programmable logic controllers (PLCs) and computer numerical control (CNC) systems allow for precise adjustments and operation, reducing the need for operator input and significantly increasing production speeds.

The adoption of automation and robotics in Power Press operations has a profound impact on both efficiency and safety. From an efficiency standpoint, automated systems can operate at a consistent pace without fatigue, enabling round-the-clock production with minimal downtime. This consistency results in higher output rates and reduced lead times, giving manufacturers a competitive edge in the market. In terms of safety, automation significantly reduces the need for direct human interaction with the press, thereby lowering the risk of accidents and injuries. Automated safety features, such as sensors and guards, further enhance the safety environment by preventing unauthorized access and detecting potential hazards before they become serious.

Moreover, automation in Power Presses contributes to improved product quality. The precision and repeatability offered by robotic systems result in products that meet stringent quality standards, with reduced waste and rework. This level of quality assurance is crucial in industries where components must adhere to exact specifications.

In conclusion, the integration of robotics and automation in Power Press operations represents a significant advancement in manufacturing technology. By enhancing efficiency, safety, and product quality, automation ensures that Power Presses remain an indispensable asset in the modern manufacturing landscape, poised to meet the challenges of an ever-evolving industry.

The continuous evolution in the manufacturing sector drives the demand for more durable, efficient, and safer Power Presses. Innovations in materials and design play a pivotal role in meeting these demands, offering new pathways to enhance the durability and performance of these machines. This chapter discusses the advancements in materials and innovative design features that are shaping the future of Power Press technology.

The development of new materials has significantly impacted the durability and lifespan of Power Presses. High-strength alloys, composites, and treatments are being introduced to withstand the harsh operational conditions of pressing operations. These materials are engineered to offer superior resistance to wear, corrosion, and fatigue, thereby extending the service life of the press components. For instance, the use of titanium alloys in critical parts can result in a lighter, yet stronger press structure, reducing the overall stress on the machine during operation.

In addition to material innovations, modern Power Presses are benefiting from a host of innovative design features aimed at improving performance and usability. These include modular designs that allow for easy customization and scalability according to production needs. Ergonomic features are also being integrated to enhance operator comfort and safety, such as user-friendly interfaces, adjustable controls, and improved visibility of the work area.

Energy efficiency is another area where design innovations are making a mark. Newer Power Presses are being equipped with energy-saving features like regenerative drive systems, which capture and reuse energy, significantly reducing the power consumption of the press. Furthermore, the integration of advanced sensors and predictive maintenance technologies helps in optimizing machine operation, predicting failures before they occur, and reducing unplanned downtime.

The push towards automation has also led to the incorporation of smart technologies in Power Presses. Features such as real-time monitoring, remote control capabilities, and artificial intelligence (AI) for process optimization are becoming standard, setting new benchmarks for efficiency and productivity.

In conclusion, the innovations in materials and design of Power Presses are setting new standards for durability, efficiency, and safety in the manufacturing industry. These advancements not only improve the performance of Power Presses but also contribute to the sustainability and competitiveness of manufacturing processes in a rapidly changing industrial landscape.

Power Presses play a crucial role across a wide array of industries, transforming raw materials into precise components needed for various applications. From automotive manufacturing to the burgeoning field of renewable energy, the versatility of Power Presses enables the mass production of parts with unparalleled efficiency. This chapter explores the industry-specific applications of Power Presses and their emerging roles in new sectors.

Automotive Manufacturing: In the automotive industry, Power Presses are indispensable for producing a wide range of components, including body panels, chassis parts, and interior mechanisms. Their ability to handle large volumes and maintain high precision makes them essential for meeting the stringent quality standards of the automotive sector.

Aerospace Components: The aerospace industry relies on Power Presses for fabricating parts that require extreme precision and durability. From structural elements to engine components, these presses allow for the production of parts that meet the critical safety and performance standards of aerospace applications.

Consumer Electronics: In the fast-paced world of consumer electronics, Power Presses are used to create components of devices such as smartphones, laptops, and household appliances. The technology enables manufacturers to rapidly produce parts with the intricate designs and tight tolerances required by modern electronic devices.

Renewable Energy Sector: As the global demand for renewable energy solutions grows, Power Presses are finding new applications in the production of solar panels, wind turbine components, and other renewable energy technologies. Their precision and efficiency are key to developing durable, high-performance parts that can withstand the rigors of renewable energy environments.

Biomedical Engineering: The biomedical engineering field is another area where Power Presses are making a significant impact. They are used to manufacture medical devices and implants with the high precision and hygiene standards required for medical applications. This includes components for surgical instruments, orthopedic implants, and other critical healthcare equipment.

In conclusion, the wide-ranging applications of Power Presses highlight their importance in today's manufacturing landscape. From traditional industries like automotive and aerospace to emerging sectors such as renewable energy and biomedical engineering, Power Presses continue to drive innovation, efficiency, and quality in manufacturing processes worldwide.

Selecting the appropriate Power Press for your manufacturing needs is a critical decision that can significantly impact your operation's efficiency, productivity, and overall cost-effectiveness. This chapter outlines key considerations such as capacity and size, load requirements, space and infrastructure needs, and a cost-benefit analysis to guide you in choosing the right Power Press.

The capacity and size of the Power Press are among the first factors to consider. This involves understanding the maximum force or tonnage the press can exert and ensuring it aligns with the materials and thicknesses you intend to work with. Additionally, the physical size of the press should fit within your available workspace without hindering operations or safety protocols.

Assessing the specific load requirements of your production processes is essential. This includes not only the maximum force needed but also the type of operations you'll be performing, such as punching, bending, or forming. Understanding these requirements will help determine the type of Power Press (mechanical, hydraulic, or pneumatic) that best suits your needs.

Space and infrastructure considerations are crucial for accommodating a new Power Press. Evaluate the floor space required, including additional room for material handling and operator movement. Infrastructure needs, such as electrical supply, foundation strength, and ventilation, must also be taken into account to ensure the press operates efficiently and safely.

Conducting a cost-benefit analysis is vital in the decision-making process. This involves comparing the initial investment and operating costs of different Power Press models against the expected productivity gains, operational efficiencies, and potential for future growth. Consider factors such as energy consumption, maintenance requirements, and the availability of spare parts and service support. A thorough cost-benefit analysis will help you make an informed choice that aligns with both your current needs and future objectives.

In conclusion, choosing the right Power Press requires a careful evaluation of your manufacturing requirements, space constraints, and financial considerations. By thoroughly assessing these factors, you can select a Power Press that meets your production goals, offers scalability for future growth, and delivers the best return on investment.

In conclusion, the role of Power Presses in modern manufacturing cannot be overstated. With advancements in technology, safety, and automation, these machines have become more efficient, reliable, and safer to operate. Whether you're in the automotive, aerospace, consumer electronics, or emerging sectors like renewable energy and biomedical engineering, a Power Press can significantly enhance your production capabilities.

As a leading manufacturer of Power Presses, JDM is at the forefront of this technological evolution, offering a wide range of machines designed to meet the diverse needs of global industries. Our commitment to innovation, quality, and safety ensures that our clients receive the best solutions for their manufacturing challenges. Visit our website at https://www.jdmpresses.com/ to explore our products and discover how JDM Power Presses can revolutionize your manufacturing processes.

The main difference between a mechanical and hydraulic power press lies in their driving mechanism and operational capabilities. Mechanical power presses utilize a motor-driven mechanical flywheel to exert force, offering high speed and consistency for repetitive tasks. They are ideal for high-volume production. Hydraulic power presses, on the other hand, use hydraulic fluid to generate force, providing greater control over the pressing speed and pressure. This makes them suitable for applications requiring precise force application and for working with various materials and thicknesses.

Maintenance frequency on a power press depends on the machine's usage intensity and the manufacturer's recommendations. However, a general guideline includes daily inspections for cleanliness and proper lubrication, weekly checks of mechanical parts for wear and tear, and monthly examinations of electrical systems and safety devices. Additionally, an annual comprehensive check by a professional technician is advisable to ensure optimal performance and safety.

Key safety features in a power press include light curtains or guards to prevent operator hands from entering the working area, dual-hand controls to ensure the operator's hands are away from the dies, emergency stop buttons that are easily accessible, and overload protection to prevent damage to the press and dies. Additionally, modern presses may include sensors and monitoring systems to detect malfunctions or misalignments early.

Yes, power presses can be customized to meet specific industrial applications. This can involve modifications to the press frame size, force capacity, die space, and automation features. Manufacturers often offer customization options to accommodate unique production requirements, such as specific material handling systems, integrated quality control systems, and specialized tooling.

Setting up a new power press involves several initial steps: ensuring the installation site is prepared with adequate space, foundation strength, and electrical supply; carefully unloading and positioning the press according to the manufacturer's instructions; installing and calibrating the press, including adjusting the stroke and pressure settings; and finally, conducting a test run with material to verify the setup before beginning full production. It's also crucial to train operators on the specific model's safety and operational procedures.